Integrated digital order fulfillment, powerful data analytics and unheated food lockers simplify operations and improve customer experience

In recent years, many top foodservice brands have introduced fantastic mobile-optimized store designs. These designs always include food lockers to help manage the growth in off-premise orders and provide fast, contactless pickup. People often assume these are heated food lockers. When seen from a narrow kitchen equipment mindset, it’s easy to see why operators sometimes believe they need heated lockers for hot foods and refrigerated lockers for cold foods.

However, we believe it’s better to look at this decision considering the whole picture including associate and customer experience, and kitchen operations. When you choose a food locker system with advanced software that can be fully integrated with your existing tech stack and provide powerful data analytics, the “hot or cold” question becomes moot.

Now you can shrink the time from order intake to customer pickup. This ensures a faster order handoff, minimal “dwell time” to ensure food freshness, optimal timing of customer notifications and maximum locker utilization.

Here’s why intelligent food lockers with ambient-temperature compartments are the smarter choice. And remember, we are the company that has rolled out thousands of heated food lockers, the most in the industry by a wide margin.

Two demands for foodservice operators

Every foodservice operator faces two ever-present realities. They know the best way to ensure customers receive fresh, high-quality food is to minimize its “dwell time” – the time between the end of the food preparation process and the time the order is delivered to the customer. The longer the dwell time, the more you have to rely on expensive “boosters” such as warming devices or refrigeration, to try to keep that food fresh. Of course, these “boosters” have hidden downsides as well (i.e., over-melting cheese, spoiling condiments, etc.)

Foodservice operators are also well aware that every customer expects to receive all the items he or she ordered, every time they order. Do this, and they’re satisfied. Miss just one item, and you have an unhappy customer.

Given these two realities, let’s look at how an operator can provide an outstanding associate and customer experience by scoring exceptionally high in both areas.

Reduce customer wait while you minimize dwell times

We know that customers see fast service as critical to a great experience. In fact, shorter wait times for in-store pickup are now the consumer’s #1 priority. That’s why brands work so hard to reduce wait times at the counter. With automated food lockers, the operator can not only minimize or eliminate wait times for order pickup, but also reduce the time food spends in the locker, or the “dwell time.” It’s the magic bullet every foodservice operator needs to hit the sweet spot in customer satisfaction.

So how does a foodservice operator impact dwell time? It requires integrated processes and systems plus good data and analytics.

A foodservice operator must start by measuring two things: order create-to-load time (the average time from the receipt of the order at the restaurant to the loading of the order into a food locker) and dwell time (the time between the end of the food preparation process or loading into the food locker and the time the order is picked up by the customer.)

Once you have this data, you can analyze and use it to achieve consistency and minimal times for both.

Having greater consistency in your processes provides you with a more accurate order ready estimate on the front end. The integrated systems allow you to provide order status updates to the customer, if desired, and send the order ready notification at the optimal time in the make process so you better match the loading of the order to the customer’s arrival.

Minimizing both create-to-load and dwell times increases your throughput while reducing the standard deviation on your operation’s average create-to-load and dwell times, enhancing consistency.

We’ve seen operators achieve dwell times of 5 to 6 minutes for over 90% of their orders, and that’s with minimal time focused on achieving consistency and reducing create-to load times. There’s potential to reduce dwell times even more as these processes are streamlined over time.

Second, how does a foodservice operator make the order pickup process as simple and error-proof as possible?

Keep in mind that almost all foodservice operators offer a combination of hot, cold, and ambient-temperature items. On the surface, this may seem like an argument for temperature-controlled compartments. However, let’s examine this approach relative to simplicity of operations (see the point above about minimizing dwell times relative to food quality.)

How heated lockers and refrigerated lockers increase complexity

Using both heated lockers and refrigerated lockers can get complicated quickly, and requires a number of non-optimal tasks and decisions.

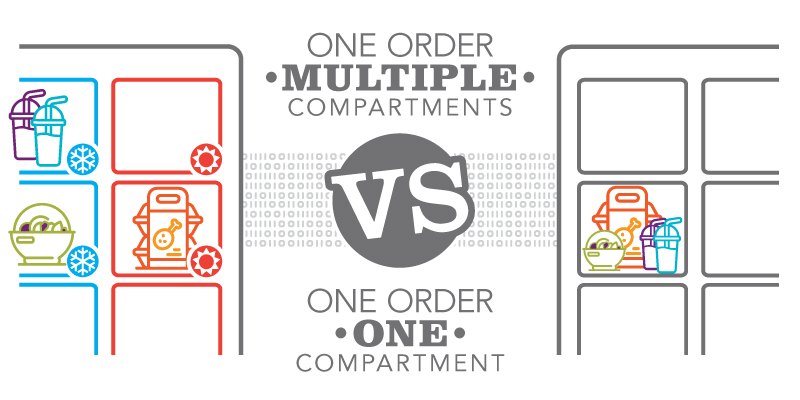

1. Since many orders include a combination of hot, ambient, and cold food items, you’re forced to split a single order across multiple compartments. This adds touchpoints for employees who now have to open doors in addition to placing orders in multiple compartments, a process that’s ripe for error.

2. Splitting orders between two compartments significantly increases the likelihood that your customer will forget the second compartment during their order pickup. And they won’t be happy when part of their order is missing.

3. You’ll need to purchase and operate up to two times the number of compartments to manage the same number of orders, since the ratio of heated to refrigerated items can vary greatly across seasons and menus.

4. You must accurately predict the number of hot, ambient, and cold compartments needed in advance, and hope the allocation matches the actual mix of orders. If not, you will have orders ready but with no place to load them, even though you may have unused compartments.

5. Then there’s this simple fact: Temperature control of foods adds cost to the device, reducing the ROI, increases total ownership costs through higher energy use, and increases the points of failure in the device.

Why ambient lockers are the right choice

Instead of thinking in terms of heated lockers and refrigerated lockers, remember “simpler is better.”

Ambient-temperature lockers are simpler mechanically, of course, and also help you maximize asset utilization. They allow you to put the entire order into one compartment, side by side. This makes both the associate loading process and the customer pickup process much less complicated.

It’s no longer necessary to pre-plan the allocation of heated and chilled compartments. Any order can go in any compartment – it’s that simple. This ensures maximum utilization of every locker compartment.

This is why there is so much more to consider than simply placing a locker box (with or without temp controls) at the end of the food make line. To truly optimize order pickup, you need a fully integrated, truly smart locker that is a core component of a complete digital order fulfillment process. That locker needs to support seamless integration with back- and front-of-house systems and processes, capture the data to measure the entire process, and provide the data and analytic capabilities to continuously improve both the customer experience and the kitchen operations.

With the right system in place – an ambient, highly intelligent food locker system such as those from Apex Order Pickup Solutions – foodservice operators can delight customers with simple, easy pickup of fresh, high quality food and do so with minimal cost.